The Challenge

A solar panel installer in Scotland, UK approached flowio with business challenges involving internal admin, design and operational time. Manual estimates and proposals straining the capacity of a small team. Over 30 hours a week was being invested into drawing up estimates for leads looking to have solar panels installed on their house. A key challenge for them was the ability to understand if the leads property was suitable for solar in the first place. Often resulting in poor quality leads that lived in flats or listed buildings, which can be unsuitable for solar panel installations.

What started as an AI consultancy engagement to identify operation efficiency gains with automated workflows became a project to build a custom app with specific requirements to help grow solar installation sales and reclaim manual time internally.

Key Pain Points

- Admin Time: Over 12 hours per employee spent on planning proposals

- Lead Qualification: Engineers were fully booked

- Travel Efficiency: Staff spent 8+ hours per week sending payment reminders manually

- Tenant Onboarding: New tenant paperwork took 3-5 days to process

"We knew AI has potential to level up the way we do things at EBC - we needed someone who "

The Solution

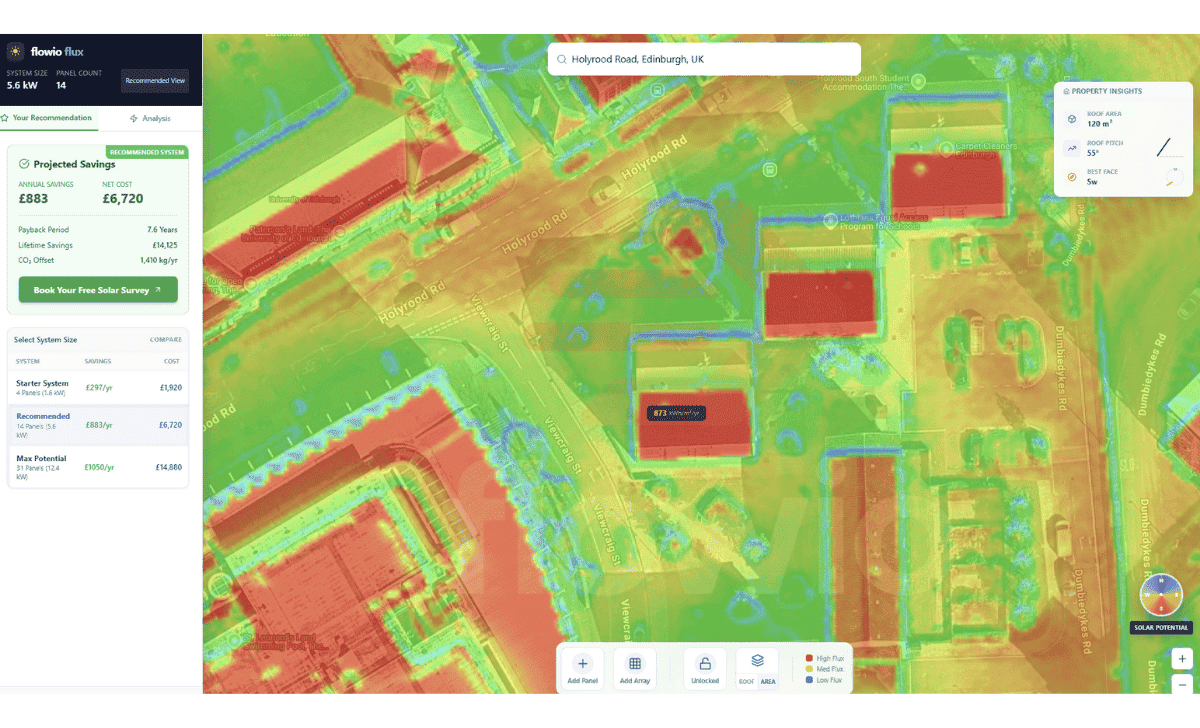

flowio developed a custom app for their business utilising the Google Solar API within Google Cloud Projects. The app ingests a users address and postcode, and with Google Maps we engineered overlays of flux levels (solar intensity) mapped to individual property roofs.

Alongside this, we implemented the

ability to analyse the pitch, azimuth and volume area of individual roofspaces - allowing solar

installers to quickly determine a proposal plan and ideal solar panel kit for each lead with kWh

estimations per month based on geographic area.

As an additional feature, flowio also developed a custom panel designer tool which

allows planners to place panels on top of the roof at an accurate scale in a

number of custom orientations and formations to visually show the customer what their roof would look like

with solar panels installed.

Roof Area Detection

Utilising Google Satellite data, we developed a way for the team to quickly identify roof dimensions, pitch and azimuth - allowing for quick and accurate solar panel planning.

Solar Flux Data

flowio developed overlays of solar flux data mapped to individual roofspaces - allowing for quick and accurate solar panel planning to determine the best orientation and pitch for solar panel installations.

Regulatory Checks

Automated Edge detection and regulatory checks to determine if a property is suitable for solar panel installations.

Energy Production Forecasts

Accurate energy production estimates based on solar flux, solar panel kits, orientation and dimension to create accurate seasonal kwh estimates per month for prospects.

Implementation Timeline

From initial consultation to full app deployment, flowio developed the Solar Flux app in just 6 weeks with zero downtime and no disruption to daily operations.

What Made This Different

While many off-the-shelf tools simply overlay solar potential on a map, the Solar Flux app performs real-time geometric analysis to ensure every proposal is physically viable, and provides the user with a realistic projection of potential seasonal energy producion throughout the year.

Automated Edge Detection:

The engine utilises high-resolution aerial data to identify the exact boundaries of the roof structure. By automatically detecting ridges, hips, and valleys, the app ensures that panel layouts never overlap critical structural edges or guttering systems.

Dynamic Fire Setbacks:

Local building codes and fire safety regulations often require specific "keep-out" zones—or setbacks—to allow emergency access for fire services.

Safety Compliance by Design:

The app automatically applies these Fire Setbacks (e.g., 300mm-900mm from the ridge or eaves) based on the property's specific dimensions.

Reduced Site Survey Friction:

By accounting for these constraints during the initial proposal phase, the Solar Flux app reduces the likelihood of "unbuildable" designs, saving the engineering team hours of corrective work after a manual site survey.